Operation Theater Room Laminar Air Flow Ceiling Installation Manual

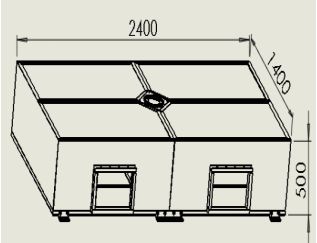

Legend: 2600*1400*5 million-level ceiling (the installation method of 100-level and 1000-level ceiling is the same)

|

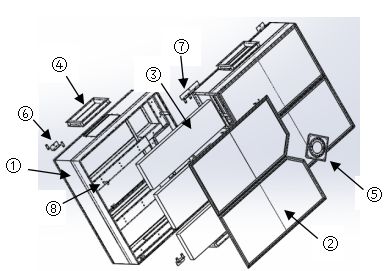

No |

① |

② |

③ |

④ |

⑤ |

⑥ |

⑦ |

⑧ |

|

Nmae |

Left box |

gauze aluminum frame |

HEPA |

flange |

airflow compensator |

Short hangers on both sides |

middle long hanger |

Compression code (screw) |

|

qty(pc) |

2 |

4 |

6 |

4 |

1 |

4 |

2 |

72 |

1. The left and right boxes are connected, the square tube is facing upwards, and there are 4 or 6 ¢14㎜ connecting holes on the square tube on the docking surface, and are connected and locked with 4 or 6 M12*70 hexagonal bolts (with gaskets). The two side panels and the gauze fixing frame are connected and locked with M6*15 external hexagonal bolts (with gaskets).

2. After the box is assembled and hoisted, after the color steel plate ceiling is drilled or the electrolytic plate ceiling is assembled, 6 expansion screws are respectively installed on the floor ceiling corresponding to the hoisting holes of the laminar flow ceiling, and locked or locked according to the site. Weld on the corresponding length of the screw or angle iron. Install a hoist on the ceiling of the floor to lift the plenum box or lift it manually to support it. The top surface of the plenum box is 300mm higher than the ceiling.

3. Hanger assembly, connect and lock 4 pieces of 50*50*100mm short hangers on the sides of the box on both sides with 2 M12*50㎜ hexagonal bolts (with gaskets), and then install 2 pieces of 50* The 50*290mm long hanger is connected and locked on the middle box with 4 M12*50㎜ hexagonal bolts (with gaskets), and the M12 screw goes through the hanger hole and is locked with an M12 nut. The static pressure box rises The lowermost side is flush with the lower plane of the color steel plate ceiling or electrolytic plate ceiling.

4. The assembly of the flange and the static pressure box is connected and locked on the box body with M6*15 hexagon bolts (with gaskets), and the connection between the air pipe and the flange is softly connected or the variable diameter joint is hard connected.

5. Install the high-efficiency filter, plug the filter into the corresponding filter frame, pay attention to the direction, and then use M10*100 to pass through the filter to press the code, and lock it with the M10 nut.

6. Laminar flow ceiling anti-rust treatment, static pressure box, parts where the paint is peeled off need to be repainted by automatic hand spray paint, screws, nuts should be replaced if they are rusty.

7. Laminar flow ceiling sealing treatment, static pressure box, filter box joints, and screw holes must be sealed with neutral glass glue in the static pressure box.

8. Laminar flow ceiling insulation treatment, static pressure box, outer wall of filter box. Use 20-25㎜ thick insulation cotton to cover it without leaving any gaps. Use rubber water for glue.

9. Finally, the airflow commentator is installed. The compensation body in the middle of the box needs to be installed after the shadow less lamp is installed, and then locked up to the corresponding screw holes of the box with 4 pieces of M5*12 stainless steel.

10. Assemble the gauze aluminum frame, use 6 spring clips on the gauze aluminum frame, fasten them to the box respectively after distinguishing the direction.

11. Clean the laminar flow ceiling, start the air supply air conditioner for 30-60 minutes, blow off the dust and slag on the inner wall of the air duct, and blow off the dust on the inner wall of the static pressure box and the aluminum frame with an air gun. Turn off the air conditioner, use Use a clean rag and alcohol to wipe the inner wall of the filter box clean.

12. Final cleaning and installation is complete.

Post time: Apr-15-2023

+86-18038493642

+86-18038493642